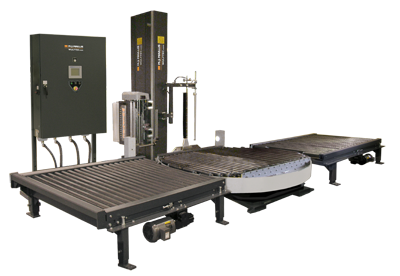

Wulftec WCA-SMART Automatic Turntable Stretch Wrappers

Features

- 4,000 lbs load weight capacity (optional 6000 lbs)

- The control panel is UL508A approved

- 100% structural steel construction

- 25″ ring GEAR w/ pinion gear drive

- Superior Electrical/Electronic design including Allen Bradley MicroLogix 1400 PLC with an integrated Ethernet port.

- Wulftec’s exclusive 20″ NO-THREAD® Powered Pre-Stretch Carriage (30″ optional)

- Readily available non-proprietary parts

- Allen Bradley Monochrome Touch Screen – play an active part in avoiding operator errors by offering a great versatility for customized information and alarm diagnostic

Specifications Production Rate: 70 loads per hour

Machine Dimensions: 135″ L x 199″ W x 100″ H

Maximum Load Size: 48″ L x 48″ W x 80″ H

Load Weight: 4000 lbs

Approximate Shipping Weight: 4750 lbs

Electrical Requirements: 230 V / 2 ph / 60Hz 20A

Pneumatic Requirements: 3 cfm @ 80 psi

Controls:

- 24V control system

- Allen Bradley CompactLogix L16ER PLC with an integrated Ethernet port

- Allen Bradley PanelView Plus 600 color touch screen interface

- Sick autoheight sensing photoeye with on/off mode

- On Stand NEMA 4/12 control cabinet

- Power on/off lockable switch and indicator light

- One panel mounted emergency stop station

- Manual carriage Up/down function

- Manual function for turntable rotation fwd

- Manual clamp jog on touch screen

- Reset function

- Separate top and bottom wrap selection (0-9)

- Single carriage speed

- Conveyor jog fwd (Fwd / rev optional*)

- Alarm beacon

- Intuitive alarms diagnostic on touch screen

- Current overload protection

- Double brush dust tight slip ring

- 230VAC motors & variable frequency drives with contactor driven conveyors

- Film force to load control

Structure

- 14 gauge formed steel tower

- Heavy duty structural steel construction

Film Delivery System

- 20″ NO-THREAD® Powered Pre-Stretch Carriage

- 1 HP 230VAC motor with Allen Bradley variable frequency drive

- Lifetime warranty on pre-stretch rollers blue compound

- Film force release for easy pull at start and end of cycle

- 50% to 300% prestretch ratio preset to customer spec, std 200%

- Sensing device for film out/broken with visual alarm

- Electronic film tension control with analog sensor

- Film roping bar

- Lexan roller cover for operator safety

- Proximity sensor on carriage gate to ensure gate is properly closed

Film Tail Treatment

- Automated Cut/Clamp & Wipe system

- Pulse controlled cutter

- Film alignment arm & brush on film tail treatment

- Brush-on film tail treatment (Heat Seal treatment*)

Film Carriage Drive

- 1 HP 230VAC motor with Allen Bradley variable frequency drive

- Two #40 carriage lifting chains

- Bearing supported maintenance free guide wheels

Turntable conveyor

- 25″ Heavy duty ring gear with pinion gear drive

- Max 16 RPM variable speed

- 1 HP 230VAC motor with Allen Bradley variable frequency drive

- Electronic soft start/stop

- Positive turntable alignment controlled by proximity sensor

- Electric brake

Turntable conveyor

- 77″ dia. 1/2″ steel plate

- 2 1/2″ dia. Rollers on 3 3/4″ centers

- All full length rollers driven

- 3/16″ wall cold rolled electric welded steel rollers

- 52″ BFR (between frame rails)

- 1 HP AC motor with contactor

- #40 ANSI chain drive

- Heavy duty cast iron flange mounted bearing

Conveyors

- 5′ in / 5′ out contoured powered conveyor with smooth transfer

- Standard 52″ BFR (between frame rails)

- Standard pass height 18″

- (Other pass heights available, please consult factory*)

- 2 1/2″ diameter rollers on 3 3/4″ centers

- 3/16″ walls cold rolled electric welded steel rollers

- Rollers driven via #40 chain

- 1 HP 230VAC motor and contactor

- Heavy-duty structural steel design, interlocking style for continuous equal roller spacing

- Heavy-duty cast iron flange mounted bearings

- 30 FPM fix conveyor speed (Other speeds available*)

Technical Information: The machine is provided with a manual including electro/mechanical schematics and drawings, maintenance program and PLC program disk