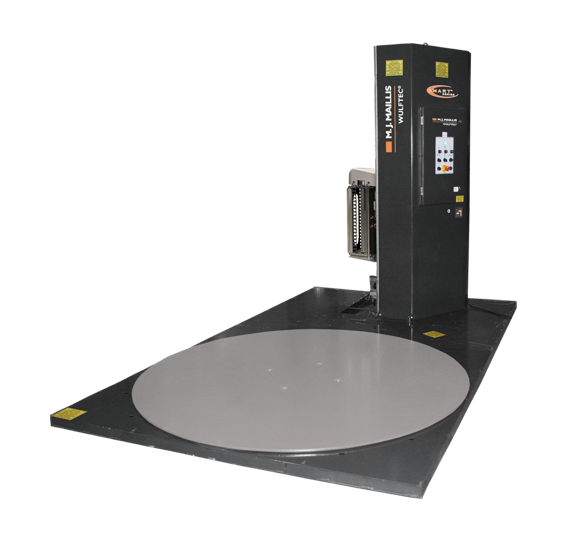

Wulftec SML-277 Turntable Pallet Wrapper Machine

The SML-277 model, a standard base low-profile turntable as the ideal stretch wrapping solution for your unique needs.

Low-profile oversized base stretch wrapper.

For large pallet loads.

Features

- 5,000 lbs load weight capacity

- NEMA 4/12 control panel dust tight and waterproof

- The control panel is UL508A approved

- 100% Structural Steel Construction

- Superior Electrical/Electronic Design including Allen Bradley MicroLogix PLC and AC drives

- Wulftec’s exclusive 20″ NO-THREAD® Powered Pre-Stretch Carriage (30″ optional)

- Easily available non-proprietary parts

- State-of-the-art electrical control panel with all finger safe electrical components

- Carriage lifting chains enclosed inside tower for operator safety

Specifications Production Rate: 55 loads per hour

Machine Dimensions: 131.50″ L x 78″ W x 86.50″ H

Load Weight: 5000 lbs

Approximate Shipping Weight: 2800 lbs

Electrical Requirements: 120 V /1 ph /60Hz /15A

Controls

- Allen Bradley MicroLogix 1000 or 1200 PLC

- 24V control system

- Current overload protection

- NEMA 4/12 control cabinet

- Autoheight sensing photoeye

- Power light indicator (Basic)*

- Power on/off switch and status light (Standard)*

- Start/stop push button

- Large emergency stop (push / pull type)

- Manual carriage up/down function

- Variable table speed (16 RPM) with automatic home position with automatic home position

- Carriage speed adjustment

- Top and bottom wrap selectors

- Reinforced wrap/manual rotation control

- Film tension adjustment

- Lack of film alarm

Structure

- 14 gauge formed steel tower

- Forklift Portable base design from both ends

- Heavy duty structural steel construction

Film Delivery System

- 20″ NO-THREAD® Powered Pre-Stretch Carriage

- 1 HP AC motor with Allen Bradley variable frequency drive

- Lifetime warranty on pre-stretch rollers blue compound

- Film force release for easy pull at start and end of cycle

- 50-400% pre-stretch ratio (preset to customer spec, Std 277%)

- Electronic film tension control with analog sensor

- Film roping bar

- Lexan roller cover for operator safety

- Proximity sensor on carriage gate to ensure gate is properly closed

Film Carriage Drive

- 1 HP AC motor with Allen Bradley variable frequency drive

- Two #50 carriage lifting chains enclosed in tower for safety

- Bearing supported maintenance free guide wheels

Turntable

- 77″ dia. 3/8″ steel plate

- 40 heavy duty non metallic lube-free table supports

- 3″ table height

- 2-3/8″ high base

- Ramp accessible on all three sides (consult factory when ordering more than one ramp)

Turntable Drive

- 0-16 RPM variable speed

- 1 HP AC motor with Allen Bradley variable frequency drive

- 50 ANSI heavy duty chain drive

- Electronic soft start/stop

- Positive turntable alignment controlled by proximity sensor

Technical Information

The machine is provided with a manual including electro/mechanical schematics and drawings, troubleshooting guide & Installation instructions